TEl: +86-13148388090

Fax:+86-571-88616515

How Tip Design Affects Suction Efficiency

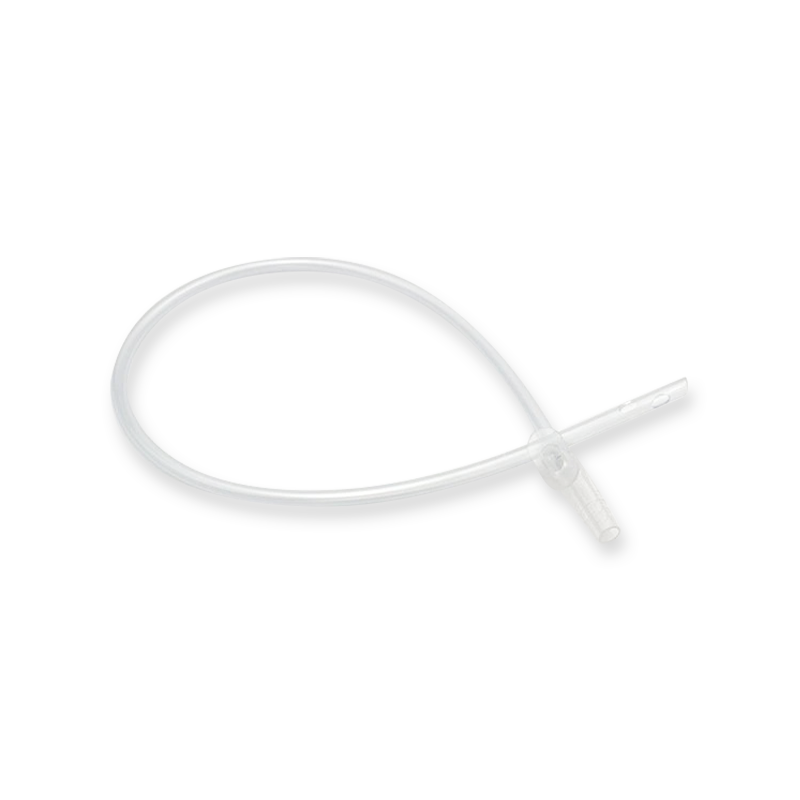

Author: admin / 2025-12-27When evaluating suction catheters, many buyers focus on size, material, or sterility. However, one of the most underestimated factors influencing real-world performance is tip design. The shape, openings, and structure of the catheter tip play a critical role in suction efficiency, clog resistance, and overall reliability.

This article explains how three common suction catheter tip designs—Standard Tip, Whistle Tip, and DeLee Tip—differ in structure and how those differences affect suction performance in various care environments.

Why Tip Design Matters in Suction Catheters

Suction efficiency is not determined by vacuum pressure alone. It depends on how effectively negative pressure is transmitted to secretions without causing blockage, collapse, or interruption of airflow.

A well-designed tip should:

- Maintain continuous airflow

- Reduce the risk of occlusion

- Allow controlled, consistent suction

- Adapt to different secretion viscosities

Even small design variations at the distal end can significantly influence performance.

1. Standard Tip Suction Catheters

Design Characteristics

- Rounded or straight distal end

- One central opening with two side eyelets

- Symmetrical and simple structure

Impact on Suction Efficiency

The standard tip design provides balanced and predictable suction. The combination of a main opening and side eyelets helps maintain airflow even if one opening becomes partially blocked.

Because of its simplicity, this design offers:

- Stable suction performance

- Lower manufacturing complexity

- Consistent results across batches

Typical Use Considerations

Standard tip suction catheters are widely used due to their versatility. They perform well in situations where secretions are moderate and uniform. From a procurement perspective, they are often the most cost-effective and universally accepted option.

2. Whistle Tip Suction Catheters

Design Characteristics

- Angled distal opening

- Elongated, oval-shaped tip aperture

- Reduced number of side eyelets or none

Impact on Suction Efficiency

The angled opening of a whistle tip catheter is designed to:

- Improve directional suction

- Reduce adherence to flat surfaces

- Enhance suction efficiency when approaching secretions from the side

This design can provide more focused suction, especially in situations where secretions tend to pool along surfaces.

However, because airflow relies more heavily on the main opening, performance is highly dependent on:

- Tip angle precision

- Opening smoothness

- Edge finishing quality

Poorly manufactured whistle tips may experience uneven suction or partial blockage.

Typical Use Considerations

Whistle tip designs are often selected when directional control and targeted suction are desired. Buyers should pay close attention to tip consistency and quality control, as minor variations can affect performance.

3. DeLee Tip Suction Catheters

Design Characteristics

- Extended distal tip with multiple small openings

- Designed for controlled, gentle suction

- Often associated with lower localized pressure

Impact on Suction Efficiency

The DeLee tip distributes suction force across several smaller openings. This results in:

- Reduced localized vacuum intensity

- Lower risk of sudden blockage

- More controlled and gradual suction flow

While overall suction force may feel less aggressive compared to standard or whistle tips, the design prioritizes flow stability and clog resistance.

From an engineering standpoint, maintaining consistent hole size and spacing is critical. Variations can lead to uneven suction distribution.

Typical Use Considerations

DeLee tip catheters are commonly chosen when controlled suction is preferred over maximum force. For buyers, manufacturing precision and inspection standards are especially important for this design.

Comparing Tip Designs at a Glance

| Tip Type | Suction Focus | Clog Resistance | Manufacturing Sensitivity |

|---|---|---|---|

| Standard Tip | Balanced | Moderate–High | Low |

| Whistle Tip | Directional | Moderate | Medium |

| DeLee Tip | Distributed | High | High |

Key Considerations for Buyers and Distributors

When sourcing suction catheters, tip design should be evaluated alongside:

- Material flexibility

- Eyelet smoothness

- Tip edge finishing

- Batch-to-batch consistency

Suction efficiency is not just a design concept—it is the result of design execution and quality control. Two catheters with the same nominal tip type can perform very differently depending on manufacturing standards.

Final Thoughts

Understanding how tip design affects suction efficiency helps buyers make more informed sourcing decisions. Whether choosing a standard, whistle tip, or DeLee suction catheter, aligning design characteristics with intended use environments is essential for reliable performance.

For manufacturers and suppliers, consistent tip geometry and inspection processes are key to delivering dependable suction catheters that meet market expectations.

English

English Deutsch

Deutsch